Palm oil is not native to Indonesia but it is from West Africa and originally brought by Dutch colonialists. Initially only 4 palm oil seedlings were planted in the Bogor Botanical Garden but now they have been planted into plantations with an area of nearly 9 million hectares, while Malaysia 5 million hectares. Currently Indonesia is the world's largest producer of palm oil, beating Malaysia with CPO production of more than 23 million tonnes / year with the number of oil palm mills reaching more than 600. Right now approximately 1,100 palm mills in Southeast Asia, and majority in Indonesia and Malaysia. Palm oil and its derivative products have become the largest foreign exchange earners of the plantation sector for Indonesia. The palm oil and its derivative products are divided into several groups namely CPO (crude plam oil), refined products of CPO, palm kernel oil (PKO), refined products of PKO, biodiesel and oleo-chemical. Naturally, palm oil business is a concern for many parties because of its role in the economic sector, which includes agriculture, industry and trade. The optimization of palm oil business continues to be done continuously for the sustainibility.

|

| Palm Oil Monument in Bogor Botanical Garden, West Java, Indonesia |

Optimalization in the agricultural sector, now it is time for Indonesia for doing intensification so that palm oil productivity can be improved. When efficiency is increased, productivity will increase as well as the profits of the palm oil business. Precision farming and internet use (

IoT = Internet of Things) are timed for use in the palm plantations. With precision farming and IoT, the need or dose of palm oil fertilizers or nutrients will be adjusted as needed, and real time soil fertility conditions and various agricultural variables can also be viewed and monitored carefully with apps or websites. The advantages and disadvantages of fertilizers or nutrients of both macro elements such as NPK and micro elements such as Fe, Mn, B, Mo, Cl, Cu, Zn in certain zones of oil palm plantations can be immediately detected, as well as various disturbances in oil palm plantations such as drought, wild pigs, pests and so on. The sensors installed in the palm oil plantation will then work with telemetry so all the data can be displayed on the screen to be analyzed and searched for the solution.

Isn't the palm oil area tens of thousands to hundreds of thousands hectares area? How to monitor and process the data? The more sensors installed in the palm oil plantations , the conditions will be more accurate reported. If we visit a modern chemical plant with sophisticated control room, see dashboard in cockpit plane or car dashboard and so then operational condition can be monitored easily. The more sophisticated the vehicle or factory then the look in the 'control room' is also more complete and sophisticated. So that's how to monitor the 'operating conditions' of the palm oil plantation with tens or even hundreds of thousands of hectares. Without knowing the condition of the plantation is like a driver driving in the 'dark', gasoline run out do not know, the engine overheating is also not known and so forth. Of course that is a high risk, many palm oil plantation failed or a lack of production due to various things 'dark' is. Thousands of data with many varieties of plantation condition then be collected and with big data can be mapped and analyzed for mapping also for the solution.

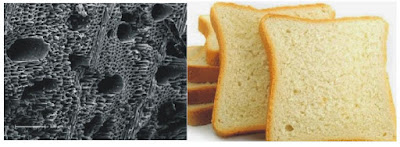

Soil fertility is vital to the farm / plantation business more specifically in palm oil plantations, so the effort to continue to maintain soil fertility should receive great attention. Of course there are many ways to continue to keep the soil fertility, including fertilization, the use of charcoal (biochar) and sheep grazing. Charcoal (

biochar) is proven to increase soil fertility by keeping soil moisture,

a microbial soil, retaining leaching, increasing soil pH, adding soil organic carbon and improving soil structure. Even with regard to climate change and the environment, the soil (biochar) that is introduced to the soil also absorbs carbon from CO2 from the atmosphere (carbon sequestration). Biochar can also survive hundreds or even thousands of years in the soil so that the benefits are very long.

There are several scenarios to produce biochar on palm oil business. Solid waste from palm oil mills such as empty bunches (EFB), fiber and shell can be used for the production of biochar. Simple to most advanced technologies can be utilized for the production of the biochar. On a large scale or industrial biochar production using continuous pyrolysis (carbonization) technology such as

JFBC. The continuous pyrolysis or carbonization may be part of the palm oil mill or CPO production as can be read here or stand alone eg using only EFB as the raw material of the pyrolysis. The high cost of fertilization or efforts to maintain soil fertility so that biochar applications have a high level of urgency as described

here.

Other efforts to maintain the soil fertility of palm oil plantations with sheep grazing. Why sheep grazing can fertilize the land of palm oil plantations? Yes, because when sheep are grazed among palm oil plantations also dump the dirt in the place, so the grass between the palm oil plantation should is not eradicated but maintained for the farm business. The sheep dung become fertilizer that fertilizes the soil. Why for sheep grazing? Why not grazing cattle or buffalo? This is because sheep farms produce more meat than cows or buffalo. The lamb/sheep is the best meat and is the world healthiest food, which is grass-fed sheep or shepherded on the grass. Grass-fed sheep will produce Omega-6 to Omega 3 ratio (O6 / O3 ratio) ranging from 1 or balanced. The Omega-6 ratio to Omega 3 states that the quality of food is in terms of health, with a range of 1 at its best or a balanced condition whereas if the O6 / O3 ratio is greater then the lower the quality of the food. Meanwhile, if big livestock such as sheep are fed grains such as soybean-based O6 / O3 ratio will be big ie 13 or more. High O6 / O3 ratio will spur the onset of heart disease, cancer and other cardiovascular diseases.The second driving force is the low consumption of meat for Indonesian which according to FAO is only 12.9 kg / year / capita or below the world average reaching 41.9kg / year / capita. The population of Indonesia with the consumption of sheep meat is very minimal or only 1/20 than the population of Australia and New Zealand but it turns the ratio of heart attacks and strokes is much higher or about 3 times the population of Australia and New Zealand. This proves that there is no relation to the consumption of sheep meat with heart disease or stroke - which is the animal of choice in the Qur'an and the shepherding of these Prophets! Sheep needs for export market especially Middle East and Saudi Arabia especially during haj season is also very high, around 8 million/year. Sheep dung will also be distributed more evenly in the palm oil plantation. Sheep breeding in the palm oil plantation will also increase profits for the palm oil plantation business itself. Even because of the vastness of palm oil plantations reaching 9 million hectares, the potential benefits are also tremendous.

As a Muslim, sheep animals also have significance. Why? In the Qur'an Surah Al An'am (6): 143-144 among eight animals in pairs (4 pairs) are two (one pair) sheep, a pair of goats, a pair of camels and a pair of cattle and sheep mentioned in the first order, of course this sheep has its own privileges, among others, sheep selected as the best animal qurban (QS Ash Shaaffaat (37): 107) and animals that are pastored by all prophets. By shepherding it among the palm oil trees, sheep farms are cheap because they feed on the grasses among the trees.

With the precision farming technology and IoT as tools applied to the palm oil plantations whose essence is to continuously monitor and maintain soil fertility and plantation maintenance by analyzing a number of variables related to the goal of optimizing palm oil production, the palm oil plantation will continues to be sustainable. Making all business activities of the palm is integrated and comprehensive with attention to environmental factors, good business management and take responsibility and with the utilization of latest technology in addition to a great opportunity to be a leader in this line of business is also the prosperity of the earth, such as the command of Allah SWT in the Qur ' An Surah Huud (11): 61.