The era of decarbonization and bioeconomy continues and continues to grow over time. While some people focus on the carbon neutral sector such as the production of biomass fuels such as wood pellets, wood briquettes or wood chips, people who focus on negative carbon seem to be fewer, including the use of CCS (Carbon Capture and Storage) and biochar production. Compared to CCS, biochar production with pyrolysis is easier and cheaper so it is projected to become a future trend. Logically, the negative carbon scenario is actually much better because in addition to reducing the concentration of CO2 in the atmosphere, while the neutral carbon scenario only does not increase CO2 emissions in the atmosphere, but does not reduce or absorb CO2 in the atmosphere. CO2 sequestration or biochar carbon removal (BCR) is currently also the most industrially relevant carbon removal technology. BCR is a key solution for real climate change mitigation today and its development is very rapid. BCR also has a vital role in the carbon removal technology portfolio.

Woody biomass, especially from wood industrial waste and forestry waste, is a potential raw material for biochar production, even this type of wood biomass is the best raw material because it can produce high quality biochar, namely fixed carbon of more than 80%. The potential for wood biomass raw materials in Indonesia is very large, estimated at 29 million m3/year from forest harvesting waste, and 2 million m3/year from wood processing industry waste including 0.78 million m3 in the form of sawdust (the yield of the sawmill industry ranges from 50-60% and as much as 15-20% consists of sawdust). And that does not include if there is a biomass plantation or energy plantation dedicated to biochar production.

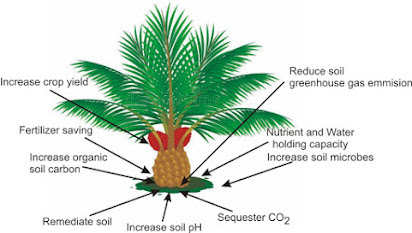

With the condition of agricultural land, plantations and forestry which are experiencing a lot of degradation, the need for biochar is also very large. Among the factors causing the decline in land fertility is the use of chemical fertilizers and pesticides for decades continuously and tends to be excessive. This causes a decline in soil quality which has an impact on crop production because it makes the land more acidic and hard which is estimated to reach millions of hectares. In addition, the price of chemical fertilizers is increasingly expensive and difficult to obtain, which results in low agricultural production, so the government is forced to import several agricultural commodities to meet the needs of the community. This actually does not need to happen considering the potential land in Indonesia is very large, it only needs to improve the condition of the land so that it can be optimal again. Making damaged land fertile is not difficult, it only takes perseverance to repair and care for the land so that it continues to be fertile.

Meanwhile, dry land consists of ultisol soil of 47.5 million ha and oxisol of 18 million ha. Indonesia has a coastline of 106,000 km with a potential land area of 1,060,000 ha, generally including marginal land. Millions of hectares of marginal land are spread across several islands, have good prospects for agricultural development but are currently not well managed. The land has a low fertility rate, so technological innovation is needed to improve and increase its productivity. Not to mention post-mining land which is almost all very damaged and also covers millions of hectares. And biochar is the right solution that can restore the condition of the land to be fertile again.

Slow pyrolysis is the best technology for biochar production. But the technology used must be efficient and emissions meet the threshold standards of the country concerned. In addition, excess heat and/or liquid products and gas products from pyrolysis should also be utilized. With the criteria for pyrolysis technology as above, in addition to the quality and quantity of products, namely biochar, can be maximized, the production process also does not cause new problems in the form of environmental pollution. This is very much in line with biochar business activities so that it becomes a solution to the problem of industrial biomass waste from wood and forestry waste as well as a solution to climate problems. Even the utilization of by-products (excess heat and/or liquid products and gas products from pyrolysis) can also encourage the emergence of other environmentally friendly and renewable products.

In economic terms, the outline can be as follows, namely with an investment of 10 million US dollars, approximately 200,000 tons of biochar with more than 400,000 carbon credits will be produced over a period of 10 years. Or if with an investment of 100 million US dollars, almost 2 million tons of biochar and more than 4 million carbon credits will be produced over a period of 10 years. And for example, with a selling price of biochar of 100 dollars per ton and also a carbon credit of 100 dollars per unit (per ton of CO2), then within 10 years the investment has increased 6 times or it only takes about 1.7 years for the initial investment to return (payback period). Of course, when the price of biochar is higher and / or its carbon credits, of course the return on capital will be faster. And that does not include the utilization of liquid and gas products from pyrolysis and excess heat which also have economic potential that is no less interesting. The trend of the future business era will not only focus on financial profit but also provide solutions to environmental problems and climate problems, and of course solutions to social problems by creating jobs.