The productivity of Indonesian coconuts is decreasing so that even though it has the largest coconut plantation area in the world. This of course makes the land less productive and the production from coconut plantations is also low. As a comparison, the productivity of Indian coconut reaches 300 grains per tree or 7.5 times that of Indonesia, which averages only 40 grains per tree per year. In addition, the number of coconut plantations that must be replanted is very large and is not proportional to the speed of replanting. Due to the lack of maintenance, there were also many areas of damaged coconut plantations, which in total reached hundreds of thousands hectares.

Indonesia has experienced the critical condition of coconut and now many coconut producing countries in the Asia Pacific region are experiencing a similar condition. Most of the coconut trees that exist are trees planted in the decade after the first world war or in the 1930s, even though the age of the coconut is around 80 years. This means that the tree is more than 80 years old or has passed its productive period. FAO has even given this warning since 2013. As a consequence, industries are experiencing a severe shortage of raw material supplies amid the increasing demand for coconut-based products, as experienced by the Sambu Group. Sambu group is the largest coconut industry in Indonesia which is located in Riau which has had to buy the coconut raw materials from West Kalimantan province in the last two years. Though Riau province itself is the largest coconut producer in Indonesia, especially Indragiri Hilir regency.

Overcoming the crisis, of course, takes time and is neither fast nor easy. A number of structured, systematic and massive efforts need to be done consistently to get optimal results and according to goals. As a product which is mainly for food and added all its parts that can be utilized, overcoming the crisis of coconut plantations or the upstream sector of the coconut industry is important. In addition, the expansion of the coconut plantation area also needs to be increased to around 6 million hectares so that the supply for industry is sufficient, in comparison Indonesia's palm oil plantations have reached around 14 million hectares. Of course that is the next step after replanting and repairing damaged coconut plantations can be overcomed.

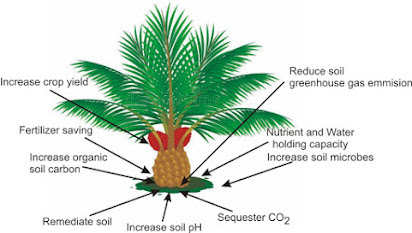

To increase coconut productivity, apart from the use of superior seeds, there are also adequate agricultural cultivation techniques. It is very important to improve soil quality so that plants can optimize nutrient uptake. No matter how good the seeds are, if the soil quality is low and farming techniques or cultivation techniques are perfunctory, the results will also not be optimal. For example, on acid soils that make nutrient absorption low and also the soil microbial activity, whatever the plant will not grow optimally. Biochar as a soil amendment is effective and efficient to improve the quality of the coconut plantation soil. Although coconut is a plant that is resistant to salinity, a decrease in salinity will also have a good impact on the coconut tree, and this can also be done with the application of biochar.

Like palm oil, coconut industrialization should also be possible. With this industrialization, the production process becomes efficient and all the coconut fruit harvested from the plantation can be processed all. Population growth that continues to increase and it is estimated that the world's population will reach around 10 billion by 2050 certainly requires sufficient food and various other supporting things such as edible oil and other coconut-derived products. Pyrolysis technology is very good for use in the coconut processing industry. This is in addition to biochar as the main product of pyrolysis with its main use in coconut plantations, excess energy pyrolysis can be used for various needs of the coconut processing industry, both in the form of heat and electricity. Coconut processing products are much more numerous and varied than palm oil. An industry will also need a continuous supply of raw materials with a certain amount and this means that the performance level of its coconut plantations must be maintained in such a way as to meet the needs of the industry and biochar application is the right solution.